What Are the Latest Trends in Parts Manufacturing?

Industry 4.0 and Smart Manufacturing Integration

IoT-Driven Production Monitoring Systems

The integration of IoT technology in manufacturing has revolutionized production monitoring, enabling real-time data collection and analysis. IoT devices, such as smart sensors, continuously gather data from various stages of the manufacturing process, providing insights into machine performance, production rates, and environmental conditions. This ability to monitor operations continuously helps in the early detection of anomalies, allowing prompt action to prevent potential delays and costly errors. For instance, smart manufacturing environments utilizing IoT systems have reported increased efficiency gains, with some case studies showing a reduction in production downtime by up to 30% due to proactive issue resolution. This improved operational efficiency is crucial for industries such as automotive parts manufacturing and precision sheet metal fabrication; where maintaining seamless production cycles is essential for meeting delivery deadlines and quality standards.

AI-Powered Predictive Maintenance Solutions

AI-powered predictive maintenance solutions are transforming traditional maintenance schedules from reactive to proactive models, maximizing manufacturing efficiency. By employing AI algorithms to predict potential equipment failures based on historical data, companies can schedule maintenance before a breakdown occurs, thus minimizing unplanned downtime and repair costs. Implementing predictive maintenance strategies has demonstrated substantial cost savings, with some companies reporting up to a 20% reduction in maintenance expenses and increased equipment uptime. A notable example is General Electric's use of AI maintenance strategies, which has significantly streamlined their operations by allowing timely interventions. These initiatives highlight the vital role of AI in enhancing the reliability of manufacturing processes and safeguarding productivity, ultimately leading to a competitive edge in precision manufacturing sectors like sheet metal fabrication.

Digital Twin Technology in Precision Sheet Metal Fabrication

Digital twin technology has become an integral tool in precision sheet metal fabrication, revolutionizing how manufacturing processes are simulated and optimized. A digital twin is a virtual replica of a physical asset or process, enabling manufacturers to simulate different scenarios and predict outcomes without physical intervention. This technology allows for the testing and optimization of manufacturing processes, improving efficiency and reducing waste. Manufacturers leveraging digital twins have witnessed notable improvements in production cycles, as the ability to visualize operations has led to more strategic decision-making and error reduction. Industry insights have shown that using digital twins in sheet metal fabrication enhances the precision and quality of parts; aligns with the increased demand for customized and complex components in sectors like automotive parts manufacturing and rapid prototyping. As Industry 4.0 advances, digital twin technology will play a crucial role in moving towards smarter, sustainable manufacturing practices.

Advancements in Material and Fabrication Techniques

Lightweight Aluminum Alloys for Automotive Parts Manufacturing

The automotive industry is witnessing a transformative shift with the integration of lightweight aluminum alloys. These materials offer significant advantages including improved fuel efficiency and enhanced vehicle performance. By reducing vehicle weight, aluminum alloys contribute to energy conservation, which is crucial given the global emphasis on reducing carbon footprints. They also enhance vehicle acceleration and handling. Research indicates a growing trend towards the adoption of aluminum over traditional steel materials in car manufacturing, driven by its ability to deliver lighter and safer vehicles while adhering to stringent environmental regulations.

Multi-Color Oxidation Treatments in CNC Machining

In CNC machining, multi-color oxidation techniques are increasingly employed to improve both the visual appeal and durability of machined parts. These treatments involve creating oxide layers that not only protect the surface but also offer a range of colors and finishes, appealing to consumer aesthetics. Market trends reveal a growing demand for multi-color strategies as they offer unique finishes not possible with traditional methods. For example, manufacturers in the aerospace and consumer electronics sectors have embraced these techniques to differentiate their products. Expert opinions highlight that such aesthetic enhancements can significantly boost brand image and customer satisfaction.

Hybrid Approaches Combining 3D Printing with Traditional Methods

Hybrid manufacturing, which combines 3D printing with traditional fabrication techniques; is gaining attention for its ability to enhance production efficiency. This approach allows manufacturers to capitalize on the flexibility of 3D printing, such as rapid prototyping and complex design capabilities, while leveraging the reliability of traditional methods for mass production. This synergy optimizes costs and reduces lead times, offering a competitive edge in parts manufacturing. For instance, the aerospace industry has successfully implemented hybrid techniques to manufacture lightweight and complex parts, showcasing the potential for innovation and efficiency improvements in production cycles.

Sustainability and Green Manufacturing Practices

Energy-Efficient Laser Cutting Technologies

Advancements in laser cutting technology have made significant strides in reducing energy consumption and enhancing sustainability in the manufacturing sector. One primary improvement is the development of more efficient laser sources that require less power to operate. As a result, manufacturers can significantly decrease their operational costs while also reducing their carbon footprint. According to studies, these energy-efficient technologies enable a 30% reduction in energy consumption compared to conventional methods, highlighting their importance in sustainable manufacturing. This not only supports environmental goals but also reinforces the industry's commitment to greener practices.

Recycled Materials in Sheet Metal Production

Integrating recycled materials in sheet metal production is an effective strategy for reducing costs and minimizing environmental impact. By utilizing recycled metals, manufacturers can limit the need for raw material extraction, thereby preserving natural resources. Certifications such as those from the Cradle to Cradle Products Innovation Institute validate the use of recycled content, ensuring that materials meet environmental and performance standards. Market statistics suggest a growing demand for eco-friendly materials, with a 20% increase in consumer preference for products manufactured using sustainable practices. This shift implies that adopting recycled materials in production processes is not only beneficial for the environment but also meets market demands.

Waste Reduction Through Rapid Prototyping

Rapid prototyping is instrumental in minimizing waste through iterative and efficient design processes. This approach allows for continuous refinement and testing of prototypes without the extensive use of materials that traditional methods require. Companies across industries are now implementing rapid prototyping to cut down on material waste, with reports indicating a reduction of up to 25% in waste levels. Moreover, experts predict that advancements in prototyping technology will further enhance waste reduction strategies, making them more sustainable and cost-effective. As such, rapid prototyping not only contributes to material efficiency but also supports a forward-looking approach to waste management in the manufacturing sector.

Innovative Manufacturing Solutions from RMT Products

Sheet Metal Parts Production for Diverse Applications

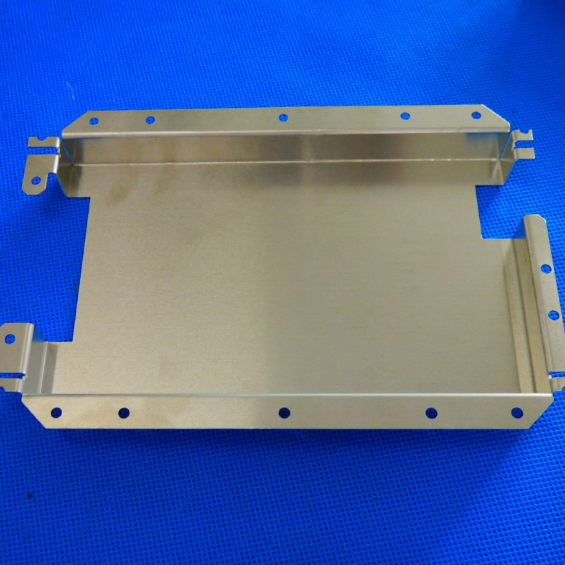

RMT's sheet metal production capabilities cater to a wide range of industries, highlighting their versatility and expertise in production. Their sheet metal fabrication processes include cutting, bending, punching, stamping, and welding, suitable for industries like automotive, aerospace, and electronics. For instance, automotive parts require precision sheet metal fabrication to meet the high standards of performance and safety. In aerospace applications, sheet metal components are vital for constructing durable and lightweight structures. RMT also provides customization options tailored to specific client requirements across different sectors, ensuring each product meets precise industry needs.

High-Precision Multi-Color Oxidation CNC Milling

RMT sets high standards for precision and quality in CNC milling, which is crucial in maintaining the competitive edge in today's manufacturing landscape. By integrating multi-color oxidation into their process, RMT provides an additional layer of customization and aesthetic appeal to their products, such as automotive parts and electronics. This oxidation process not only enhances the visual aspects of the components but also improves their corrosion resistance and longevity. Feedback from clients frequently highlights the superior quality and visual impact of RMT's manufactured parts, reinforcing their market position.

Custom Blue/Green Oxidation Aluminum Components

RMT's custom blue/green oxidation treatment for aluminum components meets the growing market demand for visually appealing and functionally superior products. The blue and green finishes not only enhance the aesthetic qualities but also improve corrosion resistance and durability, suitable for diverse applications such as automotive and consumer electronics. Success stories from satisfied clients underline how these tailored solutions have underscored the value and performance of RMT's aluminum components in demanding environments, proving their effectiveness in meeting specific industrial needs.

Automotive-Grade Plastic Injection Molding Services

RMT's automotive-grade plastic injection molding capabilities set them apart in the automotive sector by ensuring high precision and durability of parts. Meeting industry standards such as ISO 9001 and RoHS, RMT offers solutions that are critical for the evolving landscape of automotive manufacturing, where lightweight and robust materials are increasingly in demand. As the industry trends towards using more thermoplastics and composite materials, RMT's services enable manufacturers to stay ahead through innovative and eco-friendly material integration.

Natural Oxidation Turned Parts for Industrial Use

Natural oxidation in manufacturing refers to a finishing process that enhances the durability and corrosion resistance of aluminum components without altering their natural appearance. This is particularly beneficial in sectors such as aerospace and industrial machinery, where component reliability in harsh environments is crucial. The adoption of naturally oxidized turned parts is backed by industry leaders who recognize their effectiveness in prolonging product life, reducing maintenance costs, and complying with sustainable manufacturing practices.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK