Why is Sheet Metal Fabrication Essential in Construction?

Critical Role of Sheet Metal Fabrication in Construction

Structural Integrity and Safety Enhancements

Sheet metal fabrication plays a crucial role in enhancing the structural integrity of building projects by providing robust materials that can withstand various stress types. Utilizing high-quality sheet metal ensures safety in construction by minimizing risks linked to structural failures, thus underscoring its significance in construction standards. Industry studies reveal that buildings utilizing sheet metal fabrication tend to experience reduced damage from natural disasters, further demonstrating its resilience. To maintain long-term safety and reliability, regular inspections and maintenance of sheet metal structures are essential, as they align with industry regulations and standards.

Customization for Complex Architectural Needs

Sheet metal fabrication offers unparalleled customization options, allowing architects to design unique structures that cater to specific project requirements. Advanced fabrication techniques facilitate the creation of intricate patterns and shapes that traditional materials can't achieve, significantly boosting the aesthetic appeal of buildings. This ability to customize enhances client satisfaction as they can realize personalized design elements through precision sheet metal fabrication. The versatility of different metals used in fabrication enables both functional and aesthetic precision, granting architects the freedom to bring their creative visions to life and achieve superior design flexibility.

Essential Applications Across Building Projects

HVAC Systems and Climate Control Solutions

Sheet metal plays a pivotal role in the construction of HVAC systems, serving as the backbone for ducts and components that enhance airflow and energy efficiency. Its resilience and resistance to corrosion extend the lifespan of HVAC installations, consequently reducing maintenance costs. According to industry data, implementing high-quality sheet metal in HVAC systems can reduce energy consumption by up to 30%, underscoring the financial benefits tied to superior fabrication. Moreover, innovative design improvements in sheet metal fabrication offer adaptability for climate control across diverse building types, contributing significantly to effective building management systems. These attributes highlight the integral role of sheet metal in achieving optimal climate regulation and energy efficiency in construction projects.

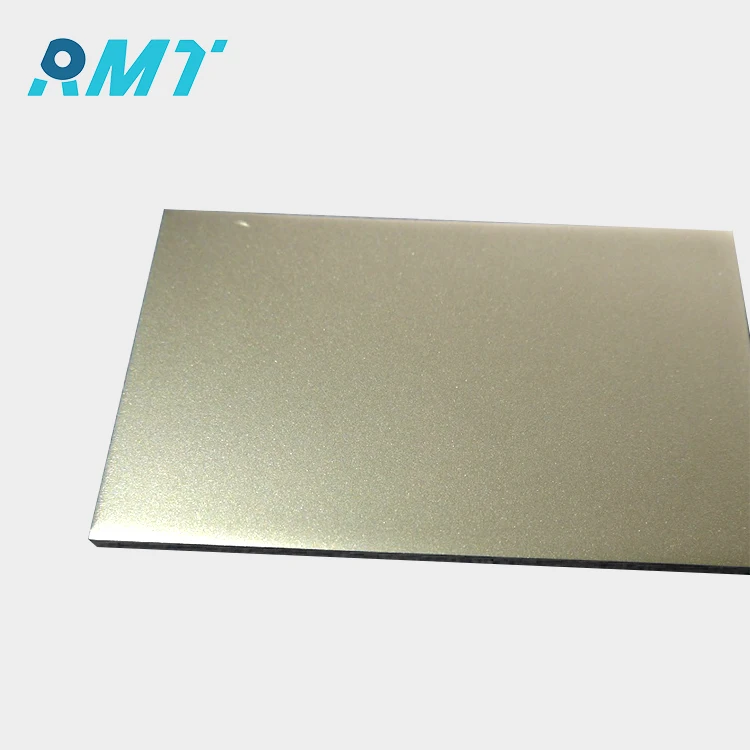

Protective Exterior Cladding and Roofing

Sheet metal is increasingly being used for exterior cladding and roofing in building projects due to its robustness against environmental elements. Its lightweight and high-strength properties help reduce the overall structural load while providing outstanding protection. Statistics reveal that buildings equipped with sheet metal cladding exhibit enhanced resistance to weather-related damage compared to those using traditional materials. Additionally, the diverse range of metal finishes available supports distinctive design opportunities without compromising structural integrity. These advantages make sheet metal a preferred choice in contemporary architectural design, ensuring both protection and aesthetic appeal.

Precision Structural Components

Precision sheet metal fabrication is essential for producing both load-bearing and non-load-bearing structural components in construction. Technological innovations now allow precise fabrication with high tolerances, ensuring all components fit perfectly during assembly. This accuracy not only minimizes material waste but also streamlines project timelines, proving cost-efficient for large-scale developments. The adaptability of precision parts manufactured through sheet metal techniques facilitates their application across various construction projects, making them indispensable. Utilizing precision sheet metal fabrication hence contributes to the overall efficiency and execution of modern construction undertakings.

Industry-Leading Fabrication Solutions

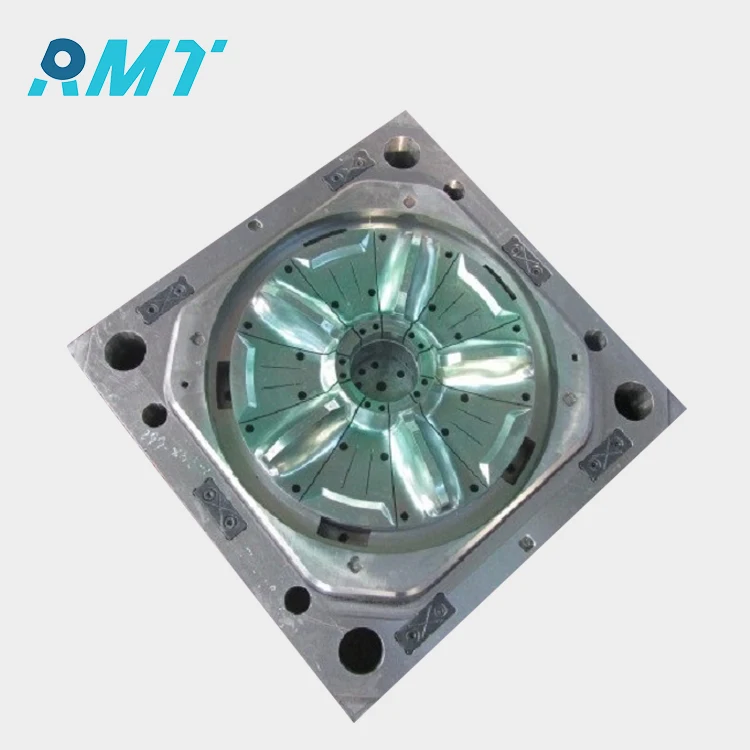

High-Precision CNC Machined Parts Production

CNC machining is integral to creating high-precision parts for construction and manufacturing industries. This technology excels in replicating intricate designs with consistency, enhancing quality over traditional methods. Research highlights that firms employing CNC systems witness reduced production times and increased part accuracy. Investing in advanced CNC machinery not only improves product offerings but also boosts customer satisfaction.

Custom Aluminum Alloy Computer Casings

Aluminum alloy casings are essential for the construction sector, providing lightweight and durable protection for electronics. Known for their thermal and electrical conductivity, these casings help in managing heat efficiently. Industry reports indicate that custom casings enhance device longevity by shielding against environmental dangers. Additionally, their design versatility provides branding opportunities within the tech-savvy construction industry.

CNC Sheet Metal Machine Parts Accessories

CNC sheet metal processes produce precision accessories vital for efficient machine operations. These technologies ensure parts are crafted to stringent tolerances, minimizing operational malfunctions. The manufacturing efficiency of these accessories helps companies adhere to supply chain schedules, thus aiding overall project timelines. Continuous advancements in CNC technology only broaden the potential of sheet metal accessories.

Stainless Steel Door Lock Components

Stainless steel fabrication is pivotal in developing corrosion-resistant door lock components that boost security and longevity in construction. Utilizing stainless steel for external locks not only extends lifespan but also reduces future replacement costs. Data from industry sources reveal that stainless steel-enhanced locking systems substantially lower break-ins compared to conventional locks. This material's design flexibility allows for diverse security specifications, suiting various building types.

Laser-Cut Metal and Stainless Steel Parts

Laser cutting technology is lauded for its precision and adaptability, allowing crafted designs in metal and stainless steel fabrication. The process minimizes material waste, optimizing resources while fostering sustainability. Businesses with laser-cutting capabilities often experience accelerated turnaround on part productions, boosting project efficiency. Custom laser-cut designs also facilitate unique branding and style elements in architectural pursuits.

Technological Advancements Driving Efficiency

Automation in Precision Fabrication

Automation significantly enhances efficiency in precision fabrication by reducing manual labor and human error in machining processes. By incorporating robots into production lines, companies can achieve higher output rates with uniform quality across fabricated components. Evidence shows that businesses embracing automation experience a notable return on investment (ROI) due to increased throughput and decreased labor expenses. Furthermore, data-driven insights from automated systems empower manufacturers to optimize designs and production schedules, leading to streamlined operations and efficiency improvements in sheet metal fabrication.

Sustainable Manufacturing Practices

The sheet metal fabrication industry is increasingly focusing on sustainable manufacturing practices to minimize environmental impact, particularly in construction. This shift includes the use of recycled materials, which helps conserve resources and lower production costs. Industry trends reflect that customers are more inclined towards companies adopting environmentally friendly methods, thus enhancing brand reputation and customer loyalty. Benchmarking data reveals that sustainable practices result in significant long-term savings and improved market positioning, making resource conservation a pivotal aspect of business strategy.

Rapid Prototyping for Construction Innovation

Rapid prototyping techniques are revolutionizing the construction industry by enabling quicker validation of designs, hence shortening project timelines and fostering innovation. This approach allows architects and engineers to conceptualize and evaluate ideas before moving to full-scale production, significantly reducing the risk of costly errors. Research notes that rapid prototyping can reduce development times by up to 50%, thereby providing a significant competitive advantage. Additionally, the use of digital fabrication tools enhances flexibility and agility in the construction process, supporting seamless integration of novel concepts into live projects.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK