Applications of Aluminium Sheet Metal Fabrication in the Automotive Industry

In the automotive industry, the demand for lightweight, durable, and corrosion-resistant materials has never been higher. Aluminium sheet metal fabrication has emerged as a key solution to meet these needs. RMT, a leading name in precision metal fabrication, has been at the forefront of utilizing aluminium for automotive applications, offering innovative solutions that enhance vehicle performance, safety, and fuel efficiency.

The Role of Aluminium in Automotive Manufacturing

Aluminium’s lightweight properties make it an ideal material for the automotive sector. It is approximately one-third the weight of steel, yet provides superior strength and durability. This makes aluminium an excellent choice for reducing the overall weight of vehicles, which in turn improves fuel efficiency and reduces emissions. RMT’s expertise in aluminium sheet metal fabrication enables automotive manufacturers to take full advantage of these benefits while maintaining high standards of quality and performance.

Key Applications of Aluminium Sheet Metal in the Automotive Industry

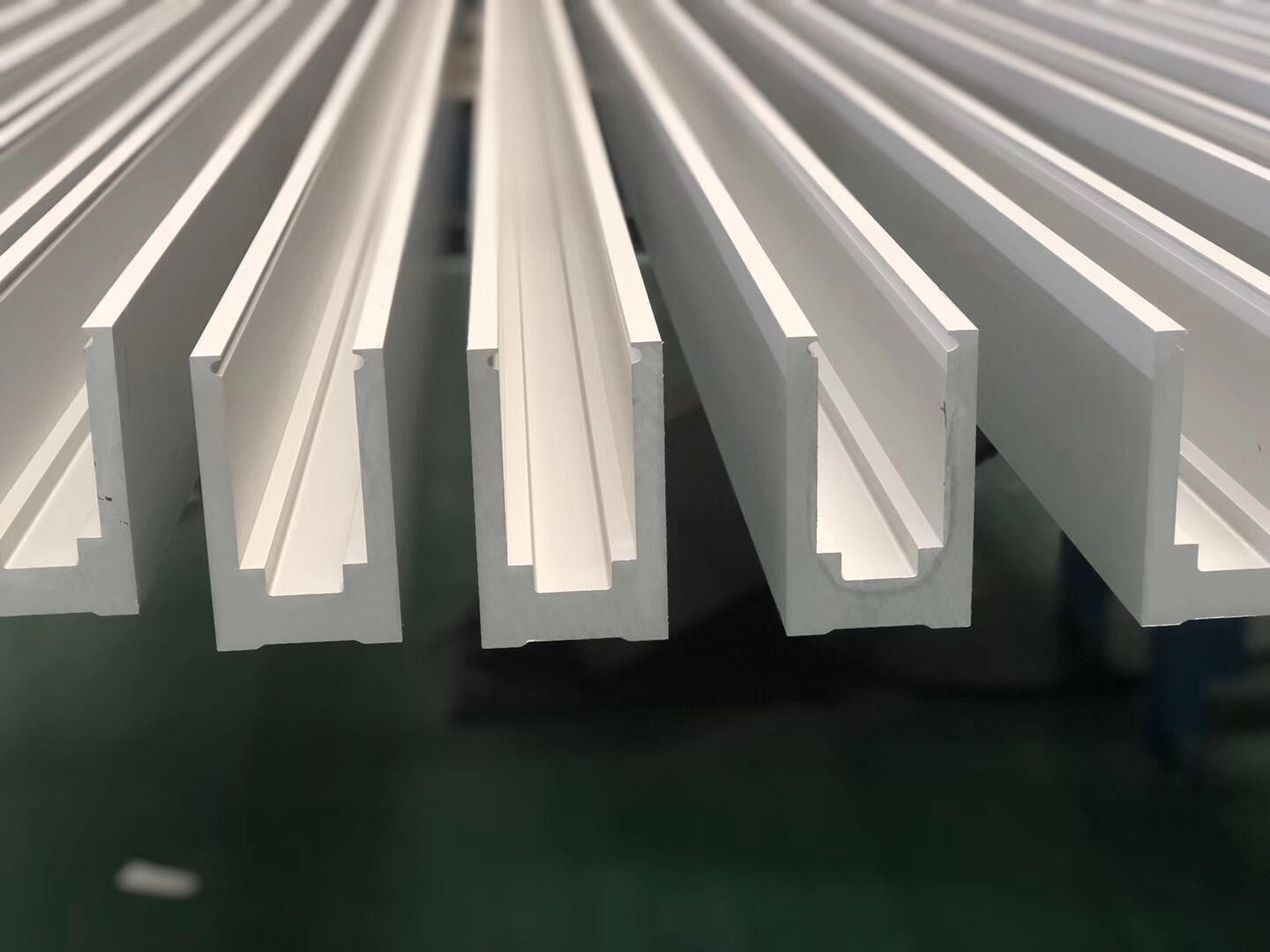

1. Vehicle Body Panels: Aluminium is widely used for manufacturing vehicle body panels, including doors, hoods, and fenders. Its lightweight nature helps in reducing the overall weight of the vehicle, contributing to better fuel economy and performance. RMT’s advanced fabrication techniques ensure that these parts meet strict quality and durability standards.

2. Chassis and Structural Components: Aluminium is also used for chassis and other structural components. Its ability to resist corrosion while maintaining strength is crucial in ensuring the long-term reliability of vehicles. RMT’s custom fabrication services allow for the production of high-precision structural components that meet the specific requirements of automotive engineers.

3. Heat Exchange Systems: The automotive industry uses aluminium in heat exchange systems such as radiators, intercoolers, and condensers. The material’s excellent thermal conductivity ensures efficient heat dissipation, enhancing engine performance and vehicle cooling systems.

4. Interior Components: Aluminium is increasingly used in the interiors of vehicles, including dashboard panels, trim, and console components. Its sleek, modern appearance and lightweight properties make it an attractive choice for automotive designers. RMT’s high-precision metal fabrication ensures that interior components are both functional and aesthetically pleasing.

Benefits of Aluminium Fabrication in Automotive Manufacturing

- Weight Reduction: By using aluminium, automotive manufacturers can significantly reduce the weight of vehicles, which leads to improved fuel efficiency and lower CO2 emissions.

- Corrosion Resistance: Aluminium’s natural corrosion resistance ensures that automotive components remain durable over time, reducing maintenance costs and enhancing vehicle longevity.

- Enhanced Performance: The use of aluminium improves vehicle performance, particularly in terms of handling and acceleration, as lighter vehicles are easier to maneuver and require less energy to operate.

- Recyclability: Aluminium is 100% recyclable without losing its properties. This makes it an environmentally sustainable material choice, aligning with the automotive industry's push for greener solutions.

Aluminium sheet metal fabrication is a game changer in the automotive industry, offering a multitude of benefits that support innovation in vehicle design and performance. RMT’s expertise in aluminium fabrication helps automotive manufacturers stay ahead of industry trends by providing high-quality, precision-engineered components that meet the demands of modern vehicle production. As the industry continues to prioritize efficiency, sustainability, and performance, RMT’s solutions are poised to play a critical role in shaping the future of automotive manufacturing.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK