Challenges And Solutions In Extrusion Parts Production

Extrusion parts are vital components applied in a variety of sectors such as automotive, construction, and consumer goods. Materials include metals and plastics and this is forced through the die to produce long objects that have the same cross-sectional profile. Of course, this method has its downsides, including taking time but is better when compared to doing it in different ways.

Common Challenges in Extrusion Parts Production

Material Selection

The importance of defining suitable parameters during the material selection in extrusion production cannot be stressed. Different materials have different characteristics and properties that can influence the extrusion process and the final product in a positive or negative way. Parameters such as melt flow index, thermal stability and even strength have to be able to work together with the extrusion parameters to avoid creating defects.

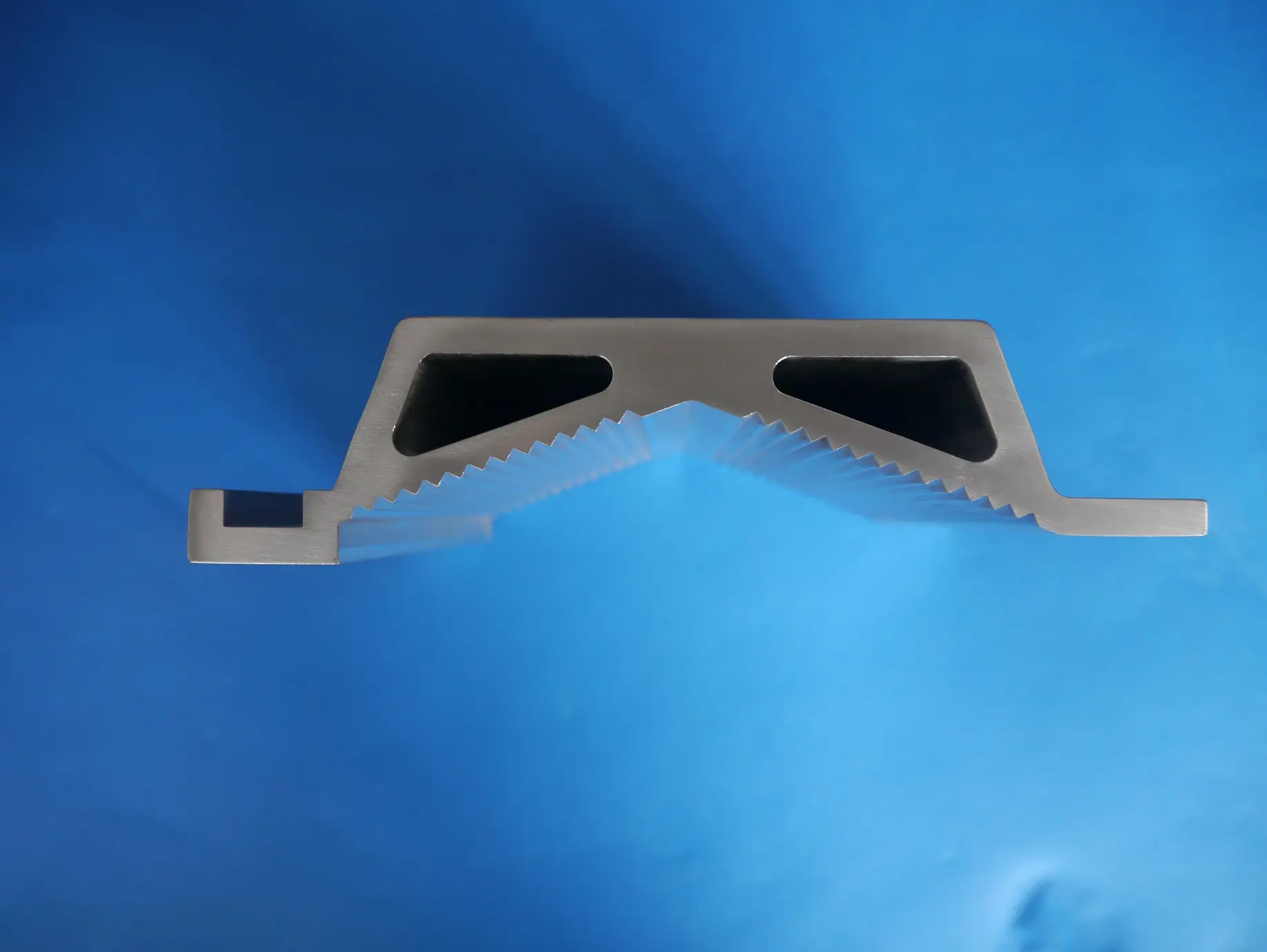

Die Design and Maintenance

The extrusion process would not be possible without a die. Defective, poorly designed, or inadequately cared-for dies are the source of imprecise shapes, surface imperfections, and thickness variants. It is absolutely critical to remember that the exact purpose and material for extrusion should match the die design.

Process Control Extrusion is expected to achieve a temperature, pressure, and speed of operation. When one or more of the process parameters is not maintained, imperfections such as warping, incomplete die filling, etc., may occur,” New technologies for process monitoring control can help maintain these parameters as well.

Solutions to Overcome Challenges

Advanced Material Testing

For future and consistent production results, advanced material examinations can assist the manufacturers in selecting the right materials which are required for extrusions. Knowing well every material’s specific features has the potential to reduce defects and improve quality.

Die Optimization Techniques

CAD software helps in designing the die as well, it also makes die design easier. Ensuring regular cleaning and inspection can take care of the natural deterioration effects and can ensure quality remains the same at all times The production of extrusion parts comes with its unique set of challenges, but with the right solutions, manufacturers can achieve optimal results.

As RMT shows , there are obstacles in the production of extrusion parts, but there are methods to get around these , One of them is providing an innovative approach and a quality extrusion part so that our customers can meet their market needs.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK