Precision CNC Machining Services

From rapid prototyping to volume manufacturing of end-use parts

Excellent quality

Fast Delivery

- Overview

- Inquiry

- Related Products

What’s CNC Machining Service

CNC (computer numerical control) machining is a widely used manufacturing process that uses automated high-speed cutting tools to form designs from metal or plastic material lblocks. Standard CNC machine tools include 3-axis, 4-axis and 5-axis milling machines, lathes and routers. The way the machine cuts the part would be different. The workpiece may remain in place when the tool is moved, the tool may remain in place when the workpiece is rotated and moved, or the cutting tool and the workpiece may move together. Computer Numerical Control (CNC) machining uses computer-guided equipment to substruct unnecessary material from the workpiece to achieve the desired shape and size. It includes CNC milling and CNC turning.

CNC milling service

CNC milling, especially 5-axis milling, can be used to create complex 3D shapes or apply machined surfaces or features to parts made of plastic or metal. The advantages of multi-axis milling machines make the CNC milling process accurate and repeatable, and can be used to create many different types of part features with complex geometries. Examples include holes, curves, grooves, angles, and channels. Milling is also ideal for making pressure die casting and injection molding tools.

CNC milling prototypes and production parts as fast as 1 day | Free standard shipping on all orders.

CNC turning service

CNC lathes allow us to turn plastics and metals from bars or blocks at high speeds. The turning process allows the production of complex external and internal geometries, including the creation of various threads. For any round parts, such as shafts, worms, and spheres, CNC turning is a more effective method than CNC milling. RMT’s turning capabilities can go from mass-produced parts all the way to prototypes.

CNC turning prototypes and production parts as fast as 1 day | Free standard shipping on all orders

Advantages of CNC Precision Machining

Compared with traditional manufacturing processes,

CNC machining has many advantages, including:

Rely on advanced machining technology

Range of materials can be machined.

Rich experience

Tighter tolerances

Shorter delivery time

Reduce labor costs

Why Use RMT for Custom CNC Machining Services?

Why use RMT for custom CNC machining services?

RMT provides customized CNC machining services for engineers, product developers, designers, etc. Our high quality machine shop can make any simple or complex custom design. We offer rapid CNC prototyping, low volume and high volume production.

Send CAD files to RMT for instant quotes and get feedback on pricing, lead times and manufacturability recommendations for your custom CNC parts. Our CNC services offer flexible production and shipping options for metal and plastic parts to meet your needs for the perfect price and product development.

Our team maintains capabilities for advanced CNC milling and CNC turning operations. Our CNC milling capabilities include 3-, 4- and 5-axis precision CNC milling services for prototype or full-featured parts, including milling, turning, EDM (Electrical Discharge Machining), wire EDM and surface grinding. Our CNC turning capabilities allow us to produce parts from a wide variety of metallic and non-metallic materials with visible tool marks or finished surfaces such as abrasive or sandblasted.

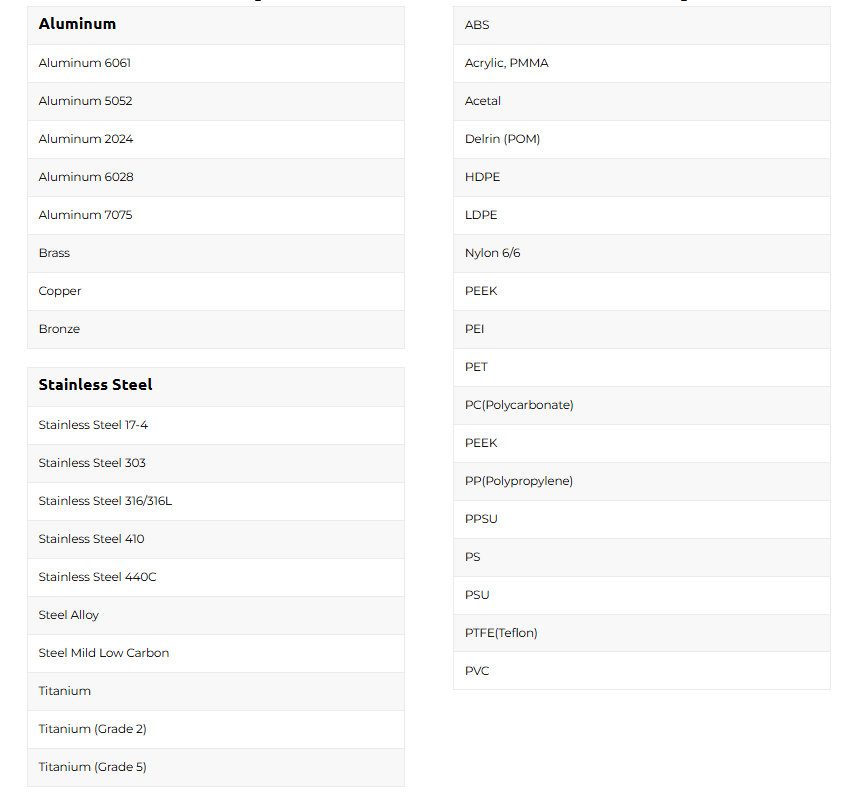

Skilled machinists operate CNC machines by programming toolpaths based on the geometry of the final part. CNC machines can cut virtually any metal and hard plastic with high precision and repeatability, making CNC machined parts suitable for use in nearly every industry, including aerospace, medical, robotics, electronics, and industrial. RMT provides CNC machining services for more than 50 materials, including aluminum, stainless steel, high-grade titanium and engineering plastics such as PEEK, POM and Teflon. Combined with other advanced features and our experienced team, your team can focus on bringing your product to market.

If you need a precision machining company that processes plastic and metal CNC parts, RMT is the way to go. Contact us today for your manufacturing solutions and details.

Advantages of CNC Precision Machining

Surface Finish for CNC machined components

If you are considering using CNC machining to make parts, it is important to know which materials and surface treatments can be applied to your CNC machined parts. RMT is located in China, not just a CNC workshop; we can also apply all types of surface treatments to CNC prototypes and production parts. Need custom CNC parts with a high-quality appearance? RMT is here to help you.

CNC machining surface finishes:

As machined

Bead blasting

Anodizing

Chem Film (Chromate Conversion Coating)

Passivation

Powder coating

Polishing

Electroless Nickel Plating

Silver plating

Glod plating

Zinc plating

Tolerance of CNC machining

Description |

Details |

| Maximum Running Size | Milled parts up to 3500x 1500 x 900 mm. Lathe parts up to 2,000 mm length and 1000 mm diameter. |

| Lead Time | 1-7 business days |

| Tolerances | Plastic and metal parts will be +/- 0.01mm, Detail tolerance depends on chosen material, size and geometry of part. |

| Minimum Feature Size | 0.01 mm. Depending on chosen material and size/gemoetry of part |

| Threads and Tapped Holes | RMT can make any standard thread size. We can also machine custom threads. |

| Edge Condition | Sharp edges as default |

At RMT, you can reap the benefits of the CNC Machining processing from our technical and qualified service. With our service, you can get a quote within 24 hours and lead times as quickly as 4 days, with DHL/FedEx Exress delivery in 3 days.

If you need any custom CNC machined components, contact RMT now.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK