Rapid Prototyping in Engineering: Key to Accelerating Product Development

Engineering needs to perfect its ideas, and make sure they are good enough, and framework manufacturers good enough, to be on the competition side of the market. That is, the time from an idea to product goes through a real cycle of perfection and milestones set to validate this world today is changing unbelievably rapidly. One of the solutions that came to slow down this drastic pace in engineering and become a game-changer for many was rapid prototyping. It is only fitting to say that in today’s world, Mould Makers have facilitated businesses with this technology. Companies such as RMT are bringing innovative and revolutionary concepts to market.

What Is The Need For Rapid Prototyping?

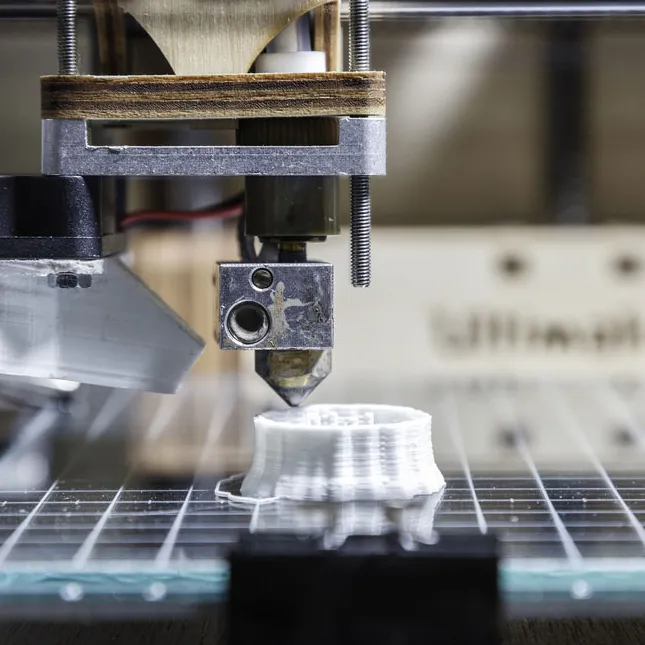

Currently, CAD software is used by engineers to design products, and rapid prototyping involves taking that computer-aided design and quickly printing a scaled replica to expedite the design process. This procedure improves the time taken between an idea and its physical representation from weeks/moths to hours and days, depending on the complexity of the idea. Also, this step is quite contrasting from Traditional prototyping, as they have extended timelines of completion. After all, with RMAT there would be numerous ways of refining and validating the concept of turning it to mass production.

Through the use of RMT’s advanced prototyping technologies, companies have the ability to acquire the functional prototypes faster than if they used other methods. This reduces the time taken in design validation and enables engineers to test any number of designs without worrying about the time and cost.

Benefits for Product Development

One of the greatest benefits of rapid prototyping is the shortening of product development cycles. For instance in automotive, aerospace and consumer electronics, simply being able to quickly prototype and test ideas enables faster decisions on implementation. With rapid prototyping more iterative approaches to development can be taken as engineers are able to redesign their product based on actual use.

Customization and Flexibility

Also, one more advantage of rapid prototyping is its flexibility. It is easy for engineers to alter the design and make a new prototype without much waiting time so a number of prototypes can be made very quickly. For example, RMT’s prototyping solutions are able to provide for numerous materials and methods of production making it possible to produce prototypes which look and act like the desired end product.

This kind of autonomy, in this case increasing decentralization, allows an organization to be responsive in a dynamic environment whether the change is initiated by the customer or by technological advancements. It also enables the experimentation of new and complex designs which may be too expensive or technologically difficult to realize through conventional approaches of production.

Future of Rapid Prototyping

With the pace at which technology evolves further strengthening the concept of rapid prototyping, its future does appear bright. The development of new materials, upgrading the printing speed and enhancing the accuracy just makes it easier to fashion prototypes that are quicker to fabricate and stronger and closer to reality. RMT is as well as continuously thinking of new tools and methods so as to allow the enterprises an edge on the area of product development.

Indeed rapid prototyping is the pillar of modern engineering and product making. Prototyping speed is increased, costs are lowered, and better quality products are created. The solutions from RMT allow business to meet challenges of high competition; through timely supply of high quality and new products. As it has been shown advances in technology will in the future also allow rapid prototyping to be a dominant tool in enhancing business’s product development cycle.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

LV

LV

SR

SR

SK

SK

UK

UK

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

EU

EU

BN

BN

BS

BS

LA

LA

NE

NE

SO

SO

KK

KK