By applying appropriate heat treatment methods, manufacturers can tailor material properties to meet specific requirements, ensuring the production of high-quality parts that can withstand the harsh operating conditions of industries such as automotive, aerospace and manufacturing.

Parts manufacturing is a cornerstone of modern industrial development, permeating the fabric of numerous industries and revolutionizing their operational capabilities. This key industry spans different applications and provides the necessary building blocks that enable machinery, equipment and systems to operate optimally in a variety of environments.

In automotive manufacturing, parts are produced ranging from precision engine components such as pistons and gears to complex electrical assemblies such as sensors and control modules. Advanced processing technologies create lightweight yet durable materials that improve fuel efficiency and enhance vehicle performance, while automation of assembly lines streamlines processes, ensures consistent quality, and reduces costs.

Aerospace is another industry that relies heavily on high-performance parts manufacturing. Here, custom-designed components must be able to withstand extreme conditions, including high temperatures, pressure and stress. From the titanium alloys used in aircraft engines to the composite materials that make up airframe structures, parts manufacturing plays a key role in advancing aerospace technology and ensuring safety and reliability.

In summary, parts manufacturing transcends traditional boundaries and touches nearly every industry involving mechanical or electronic systems. Its continuous development and innovation are fundamental drivers of progress in these industries, enabling companies to achieve greater efficiency, sustainability and competitive advantage.

In industrial manufacturing, safety is not only a priority but an ethical and legal obligation. The cornerstone of ensuring this safety is the implementation of strict quality control measures during the manufacturing of parts in each department. From aerospace and automotive to medical devices and consumer products, the integrity and reliability of each component plays a critical role in protecting users, equipment and the environment.

Quality control in part manufacturing begins with design verification, which evaluates a component's ability to meet expected specifications and functionality under specified conditions. We perform rigorous testing procedures to verify that the materials used can withstand stress, wear, corrosion or environmental hazards, thereby reducing the risk of premature failure or accidents.

Process control is another critical aspect, including continuously monitoring and adjusting manufacturing parameters such as temperature, pressure and speed to maintain consistency. This ensures that every part produced adheres to tight tolerances, eliminating dimensional errors that can lead to mismatches, vibration, or even catastrophic system failure.

Inspection methods, including non-destructive testing (NDT) techniques such as ultrasonic, radiographic or magnetic particle testing, can detect internal or surface flaws that are invisible to the naked eye. These inspections help prevent defective parts from entering the supply chain and potentially compromising safety-critical systems.

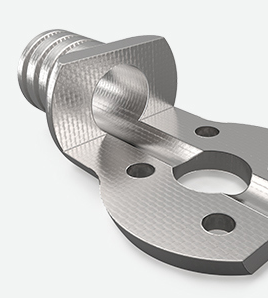

In the era of Industry 4.0, component manufacturing plays a key role in shaping the future of industrial automation. It involves delicate processes such as precision machining, additive manufacturing (3D printing) and robot-assisted assembly lines to produce complex parts with micron-level precision. These advanced methods not only ensure seamless integration of complex machinery, but also pave the way for a more autonomous, connected and flexible production environment.

The emergence of smart components and IoT devices is a direct result of complex part manufacturing. These smart components embedded with sensors and actuators can communicate with each other and with central control systems, enabling real-time monitoring, predictive maintenance and adaptive control – key elements for achieving higher levels of automation.

Additionally, modular design strategies in part manufacturing allow for rapid customization and easy expansion of automated systems. This flexibility enables manufacturers to quickly adapt to changing market demands, reduce time to market and optimize resource utilization.

The modern business environment thrives on efficient and agile supply chains, in which parts manufacturing plays a key role. Streamlining the supply chain through efficient parts manufacturing not only optimizes operating costs, but also ensures product reliability, shortens lead times and enhances overall market competitiveness.

Efficient part manufacturing starts with process optimization, leveraging advanced technologies such as automation, robotics and digital manufacturing processes. These innovations enable high-speed production, accurate part replication and minimize human error, thereby increasing throughput and maintaining consistent quality standards.

Lean principles are at the heart of streamlining supply chain operations. Implementing a just-in-time (JIT) manufacturing strategy minimizes inventory holding costs and reduces waste by producing parts when they are needed. This approach requires strong demand forecasting, strong supplier partnerships, and flexible production lines that can respond to fluctuating market conditions.

Additionally, the use of computer-aided design (CAD) and simulation tools during the development phase can help shorten prototyping cycles and speed up time to market. Concurrent engineering practices where design and manufacturing teams collaborate from the start ensures manufacturability and compatibility with existing supply chain processes.

RMT is a precision custom manufacturing provider. We provide high-quality manufacturing with on-time delivery at competitive prices. Express your requirements and once confirmed, we will develop a solution that satisfies you. Every step in the process We will continuously communicate with you at every stage so that you can understand all the information about product manufacturing.

Put the needs and expectations of customers first and center, customize satisfactory solutions with personalized services for them, and exceed customers' expectations, thereby cultivating reliable long-term trust relationships.

Guiding clients through the custom manufacturing process from concept to completion, our consultants work closely with each client to understand their unique specifications and provide strategic insights for personalized production solutions

We utilize state-of-the-art machinery and strict quality control measures to manufacture components to precise tolerances. Every part undergoes rigorous inspection to ensure micron-level accuracy to meet the most demanding specifications.

From raw materials to finished products, we meticulously adhere to strict standards, monitoring and testing every step using cutting-edge methods to guarantee consistent performance and durability in all our products.

Quality control measures in parts manufacturing include dimensional inspections, surface finish evaluations, non-destructive testing, statistical process control, and adherence to industry-specific quality standards. These measures ensure that parts meet specified tolerances and performance requirements.

Common challenges in parts manufacturing include maintaining consistent quality, managing production costs, optimizing production efficiency, addressing supply chain disruptions, keeping up with technological advancements, and meeting evolving customer demands.

When selecting materials for parts manufacturing, factors such as mechanical properties, chemical compatibility, cost, availability, and intended application must be considered. Material selection impacts part performance, durability, and overall manufacturing cost.

Lean manufacturing principles can be applied in parts manufacturing by identifying and eliminating wasteful activities, streamlining workflows, reducing inventory, improving equipment utilization, and promoting continuous improvement through employee engagement and empowerment.

Material selection depends on factors such as required strength, durability, corrosion resistance, and cost-effectiveness. Manufacturers consider characteristics like tensile strength, hardness, thermal conductivity, and compatibility with manufacturing processes.