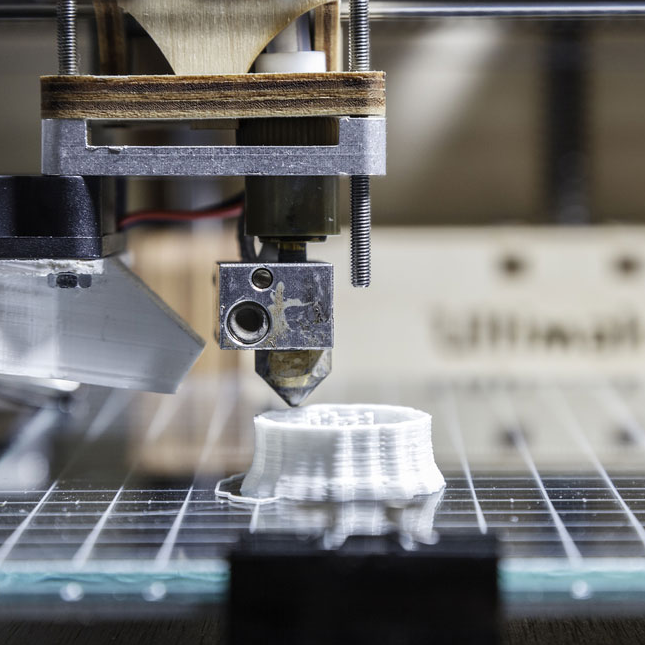

Rapid prototyping is a process that involves using computer-aided design (CAD) data to create a physical model or prototype. It uses additive manufacturing technologies such as 3D printing to build prototypes layer by layer. This iterative process enables designers and engineers to visualize and test their ideas in a tangible form, speeding up product development cycles.

Rapid prototyping changes the way products are designed, developed and manufactured. Its ability to quickly create functional prototypes revolutionizes innovation, enabling faster time to market, lower costs, optimized design and customization.

RMT is a precision custom manufacturing provider. We provide high-quality manufacturing with on-time delivery at competitive prices. Express your requirements and once confirmed, we will develop a solution that satisfies you. Every step in the process We will continuously communicate with you at every stage so that you can understand all the information about product manufacturing.

Put the needs and expectations of customers first and center, customize satisfactory solutions with personalized services for them, and exceed customers' expectations, thereby cultivating reliable long-term trust relationships.

Guiding clients through the custom manufacturing process from concept to completion, our consultants work closely with each client to understand their unique specifications and provide strategic insights for personalized production solutions

We utilize state-of-the-art machinery and strict quality control measures to manufacture components to precise tolerances. Every part undergoes rigorous inspection to ensure micron-level accuracy to meet the most demanding specifications.

From raw materials to finished products, we meticulously adhere to strict standards, monitoring and testing every step using cutting-edge methods to guarantee consistent performance and durability in all our products.

The main advantage of using rapid prototyping in product development is the ability to quickly create physical prototypes, allowing for faster iterations, design validation, and accelerated time-to-market.

Rapid prototyping provides a physical representation of a design, allowing stakeholders from different teams to visualize and provide feedback. This enhances communication, fosters collaboration, and improves decision-making throughout the product development process.

Rapid prototyping allows for quick and iterative design changes. By creating physical prototypes, designers can test and evaluate different design iterations, identify areas for optimization, and enhance the overall design quality and performance.

Rapid prototyping eliminates the need for expensive tooling and molds, reducing upfront investment costs. Additionally, it enables cost-effective small-batch production, minimizing waste and optimizing resources.

Rapid prototyping benefits a wide range of industries, including product design, automotive and aerospace engineering, healthcare and medical device manufacturing, architecture and construction, consumer goods and electronics, and education and research.