Rapid prototyping enables designers to quickly build prototypes for user testing, allowing direct feedback on usability, ergonomics and aesthetics, and continually refining the design based on real-world usage data to ensure it is tailored to user needs and test interactions behavior, improving the interface to suit user needs.

Traditionally, supply chain management has involved long lead times, high costs and limited flexibility. However, with rapid prototyping, these challenges are being overcome.

One of the main benefits of rapid prototyping in supply chain management is the ability to reduce lead times. By quickly creating physical prototypes, designers and engineers can validate and refine their designs faster.

Additionally, rapid prototyping can help reduce risk by detecting design flaws or production issues early. By identifying and resolving these issues early in the development process, costly mistakes can be avoided, reducing the risk of supply chain disruptions and delays.

Another advantage of rapid prototyping is its ability to support customization and personalization. With the flexibility of additive manufacturing technology, companies can easily customize products to meet the specific needs and preferences of individual customers. This customization feature not only improves customer satisfaction, but also helps optimize inventory management by reducing excessive inventory levels.

Rapid prototyping covers a wide range of techniques and processes that allow the creation of physical prototypes quickly and efficiently. These technologies and processes have revolutionized the product development cycle, allowing designers and engineers to iterate, test and refine their designs in a timely manner.

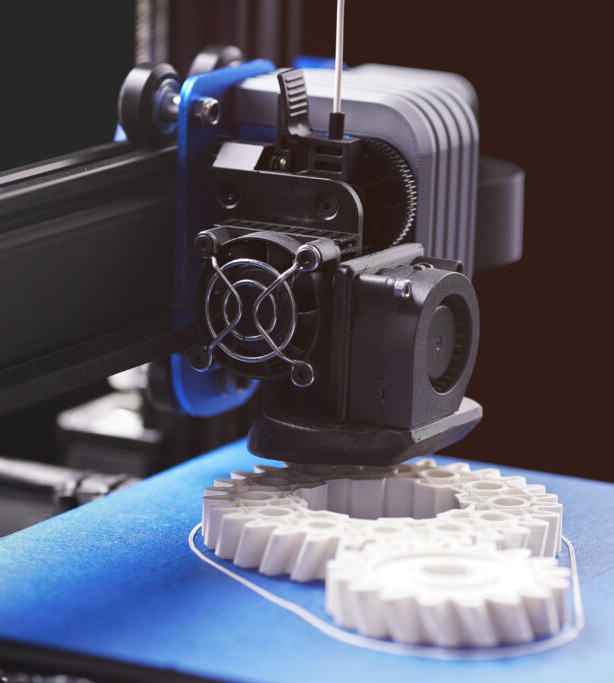

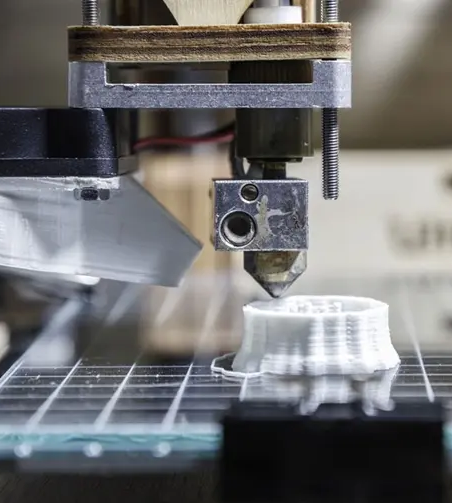

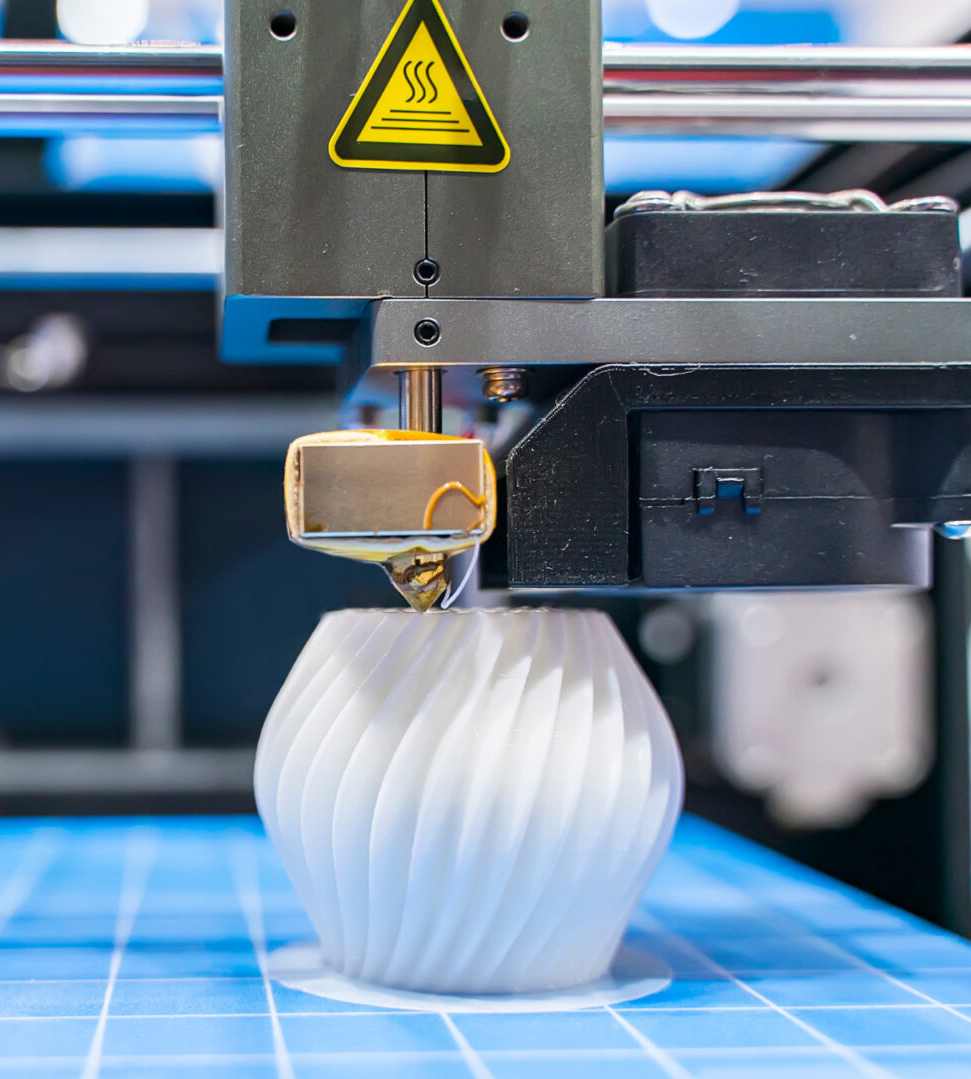

One of the most commonly used rapid prototyping technologies is 3D printing, also known as additive manufacturing. The technology works by layering thin sheets of material to build three-dimensional objects. 3D printing offers tremendous flexibility when it comes to materials, allowing the creation of prototypes for medical applications made from plastics, metals, ceramics and even biocompatible materials.

Another popular rapid prototyping technology is CNC machining, which involves using a computer-controlled machine to carve a prototype out of a solid block of material. CNC machining is highly precise and is particularly suitable for creating prototypes from metal or hard plastic materials.

In summary, rapid prototyping encompasses a variety of technologies and processes, each with its own unique advantages and applications. By exploring and leveraging these different technologies and processes, designers and engineers can choose the approach that best suits their specific needs, resulting in efficient and effective product development.

Rapid prototyping plays a vital role in driving innovation in the medical device sector. With its ability to rapidly create physical prototypes, it revolutionizes the design and development process, driving advancements in patient care and treatment.

Rapid prototyping in medical device innovation can quickly iterate and improve designs. By creating physical prototypes, designers and engineers can visualize and test their ideas, making necessary adjustments and improvements early in the development cycle.

Rapid prototyping also facilitates customization and personalization of medical devices. Each patient's needs may vary, and rapid prototyping can create a custom device that fits the individual's anatomy and specific requirements. This level of customization increases patient comfort, improves treatment outcomes, and increases patient satisfaction.

Another advantage of rapid prototyping is the ability to functionally test medical device prototypes. By creating physical models, designers and engineers can evaluate the performance, functionality, and usability of equipment. This allows early detection of design flaws or potential issues, allowing improvements to be made and ensuring the safety and effectiveness of the final product.

Additionally, rapid prototyping enables the creation of complex geometries and complex structures often required in medical devices. Additive manufacturing techniques used in rapid prototyping can produce complex features, such as lattice structures, that can enhance the functionality and performance of medical devices. This opens up the possibility for innovative designs and novel medical treatments.

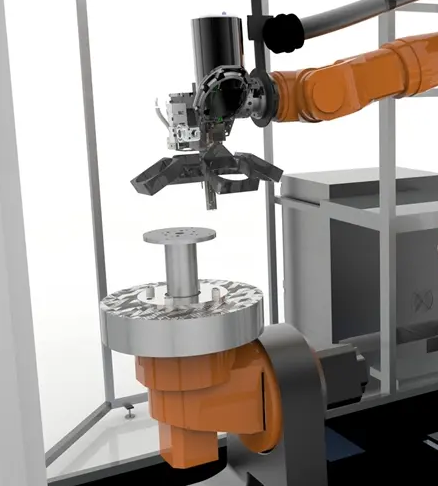

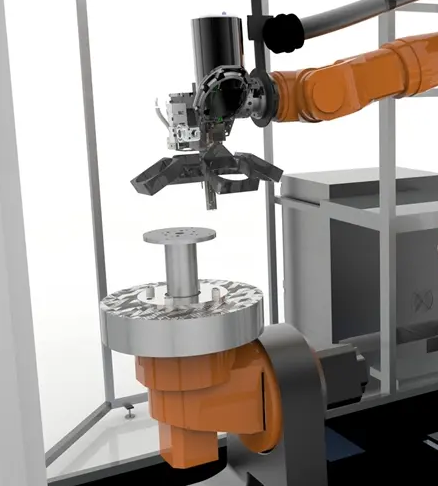

Rapid prototyping has become a driving force in advancing automation through robotics. By enabling rapid and iterative design iterations, it accelerates the development and deployment of robotic systems, paving the way for transformative applications across industries.

Rapid prototyping facilitates the customization and adaptation of robotic systems to specific tasks and environments. By using rapid prototyping technology, robotic components can be easily customized to meet unique requirements, such as size constraints or specialized functionality.

Additionally, rapid prototyping can create lightweight and optimized robotic structures. By leveraging advanced design tools and additive manufacturing technologies, designers can create complex geometries that are both durable and lightweight. This not only improves the overall performance and agility of the robotic system, but also reduces energy consumption and increases efficiency.

Additionally, rapid prototyping allows for rapid integration and testing of sensors and other components in robotic systems. By quickly creating physical prototypes, engineers can verify the integration of different sensors, actuators and control systems, ensuring seamless functionality and performance. This iterative testing process helps identify and resolve potential issues early, resulting in a more reliable and robust robotic system.

RMT is a precision custom manufacturing provider. We provide high-quality manufacturing with on-time delivery at competitive prices. Express your requirements and once confirmed, we will develop a solution that satisfies you. Every step in the process We will continuously communicate with you at every stage so that you can understand all the information about product manufacturing.

Put the needs and expectations of customers first and center, customize satisfactory solutions with personalized services for them, and exceed customers' expectations, thereby cultivating reliable long-term trust relationships.

Guiding clients through the custom manufacturing process from concept to completion, our consultants work closely with each client to understand their unique specifications and provide strategic insights for personalized production solutions

We utilize state-of-the-art machinery and strict quality control measures to manufacture components to precise tolerances. Every part undergoes rigorous inspection to ensure micron-level accuracy to meet the most demanding specifications.

From raw materials to finished products, we meticulously adhere to strict standards, monitoring and testing every step using cutting-edge methods to guarantee consistent performance and durability in all our products.

The main advantage of using rapid prototyping in product development is the ability to quickly create physical prototypes, allowing for faster iterations, design validation, and accelerated time-to-market.

Rapid prototyping provides a physical representation of a design, allowing stakeholders from different teams to visualize and provide feedback. This enhances communication, fosters collaboration, and improves decision-making throughout the product development process.

Rapid prototyping allows for quick and iterative design changes. By creating physical prototypes, designers can test and evaluate different design iterations, identify areas for optimization, and enhance the overall design quality and performance.

Rapid prototyping eliminates the need for expensive tooling and molds, reducing upfront investment costs. Additionally, it enables cost-effective small-batch production, minimizing waste and optimizing resources.

Rapid prototyping benefits a wide range of industries, including product design, automotive and aerospace engineering, healthcare and medical device manufacturing, architecture and construction, consumer goods and electronics, and education and research.